Production equipment

Total injection machines 24 units(35T~60T)

Our mold temperature controller, electrical-thermal heating system, dehumidifier and dryer and material supply system are able to meet each kind of strength and toughness request. For 2nd processing, there are ultrasonic cleaning, hot welding painting line, assemble line, printing, double injection and 600ton injection machine.

Peripheral

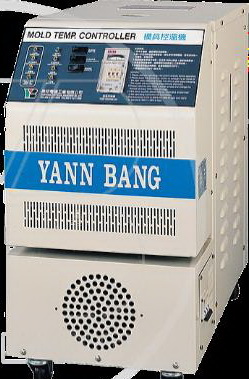

Mold temperature controller

Before plastic injection, a mold temperature controller control mold to reach expected temperature rapidly and maintain it for decreasing duration of tool preheating. It can be operated continuously without any concern of tool temperature too high.

Even if it stops in midway, it will not cause tool temperature dropping. So operators no need to wait mold temperature going up, which improves production efficiency

Air compressor

Air compressor is one of the most popular energy next to electricity. It has been widely used in industries, and the features are irreplaceable such as Energy saving, no containment and non self-ignition….etc

Material mixer

The mixing theory is thru dropping material on top of a storage can, then material falls via umbrella type tunnel. The mixer continuously mix circular upside and down to make sure stability and physical property of material.

Automatic mechanical arm

To decrease possibility of shrink, silver streaks, air bubbles and flow lines for better production quality and efficiency improvement

Material dehumidifier and dryer

To decrease possibility of shrink, silver streaks, air bubbles and flow lines for better production quality and efficiency improvement.

Power container

1. Provide emergency energy upon equipment is out of order or power cut.

2.To turn energy pressure into liquid pressure as back-up power.

3. System pressure balance. When system pressure fluctuates, it can adjust system flow and pressure variety.

conveyor

Conveyor is a machine for continuous delivering material by friction. It can deliver fragment material but also finished products. The material can be put on this transport line initial material supply stop to end material .

Mobile material heater and dehumidifier

To implement 2nd dry using vacuum theory. It can dehydrate material in very short time up to -25 degree. Intelligent interface makes operation easier. It also detect vacuum in the air to make sure stability and quality of material.

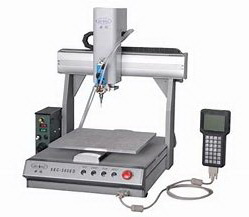

Dispensing equipment

Printing equipment

Quality assurance equipment

2.5D image measurement machine

2.5D image measurement machine is able to test every kind of complicated and precision parts’ outfit, surface dimension, angle and position, especially quality control and detailed inspection.

Pencil hardness tester

The Pencil hardness tester follows the specification “Wolff Wiborn”to manufacturer, and takes advantage of JIS and DIN standard to test pencils(6B, 5B, 4B, 3B, 2B, B, HB, F, H, 2H, 3H, 4H, 5H, 6H, 7H, 8H,9H, total 17 kinds of hardness specification). It can be tested on every kind of coating surface for identify scratch resistance

Material Stress Analyzer

So called polarimeter. It can be tested stress condition of transparency material.

MI value analyzer

MI value analyzer

It follows standard ASTM 1238. This analyzer is cable to test MI value, melting intensity, adhesion, cut speed and cut stess….etc

Force gauge

A force gauge can be applied to many kind of test items. It’s widely used in quality control especially in a lab.

Height gauge

It’s a tool of height measurement and line marking.

It uses a cursor to do precision 0.02mm height measurement and precise line marking.

Color matching equipment

Gloss meter

It’s used to test gloss of object’s surface, which is light reflectivity on surface. Basically if incident angle is bigger, gloss is higher. Vice versa

Color difference meter

Color difference meter is to detect color by naked eye. It gathers dominant wavelength from reflected light and filters light. When a meter is an observer, it detects wavelength by certain values.

Light source box

A object’s color usually varies because of light surrounded, which increase difficulty of color identification from naked eyes. Even worse it causes errors. Therese C.I.E set up a standard for light source.

So light source box follows this C.I.E standard to be designed, and it is a standard tool of color control.

Pantone color number card

International Pantone color number card is used to color pick, contrast, communication. It’s also a tool of international standard of color.

Production equipment

Pad printing machine

Screen printing machine

Hard coating equipment

Pending zone

Ultrasonic cleaning zone

Heating dryer zone